water turbine gear units

Home

• High operational reliability

• Oil-free shaft end

• Available with oil retaining tube

• Strong input shafts and bearings for absorbing high, external axial loads

A water turbine is a turbomachine that converts the potential flow energy contained in water into mechanical energy; this mechanical energy is subsequently converted into electrical energy in a generator. The gear units for water turbines gear up the low turbine speed into a very high generator speed. They also convert the torque that is output by the turbine and transmit it to the generator. The extreme transmission ratio and the high speed result in particularly high loads on the rolling bearings. The gear units are therefore equipped with bearings of the highest quality in order to reduce friction losses to a minimum.

The mounting position is usually vertical. The gear units feature the proven "dry well" design, which prevents oil leakage and protects the environment.

Applications

• Hydraulic power generating plants

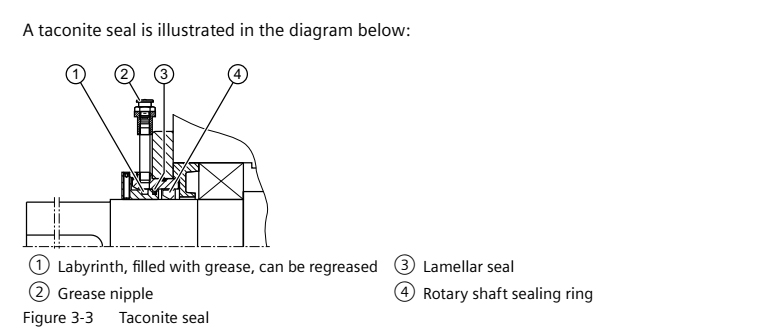

Taconite seal

The taconite seal is a combination of two sealing elements:

• Rotary shaft sealing ring to prevent the escape of lubricating oil

• Grease-filled dust seal (comprising a labyrinth and a lamellar seal) to allow operation of the

gear unit in extremely dusty environments

The taconite seal is ideal for use in dusty environments

Oil level monitoring system

Depending on the order specification, the gear unit can be equipped with an oil level monitoring system based on a level monitor, a level switch or a filling-level limit switch. The oil level monitoring system has been designed to check the oil level when the gear unit is at a standstill before it starts.

Bearing monitoring (vibration monitoring)

Depending on the order specification, the gear unit can be equipped with vibration sensors,

sensors or with threads for connecting equipment for monitoring the rolling-contact bearings or gearing. You will find information about the bearing monitoring system design in the separate data sheet in the complete documentation for the gear unit.

As an alternative, measuring nipples can be attached to the gear unit to prepare it for monitoring