Single & Tandem drives

Single & Tandem Drives

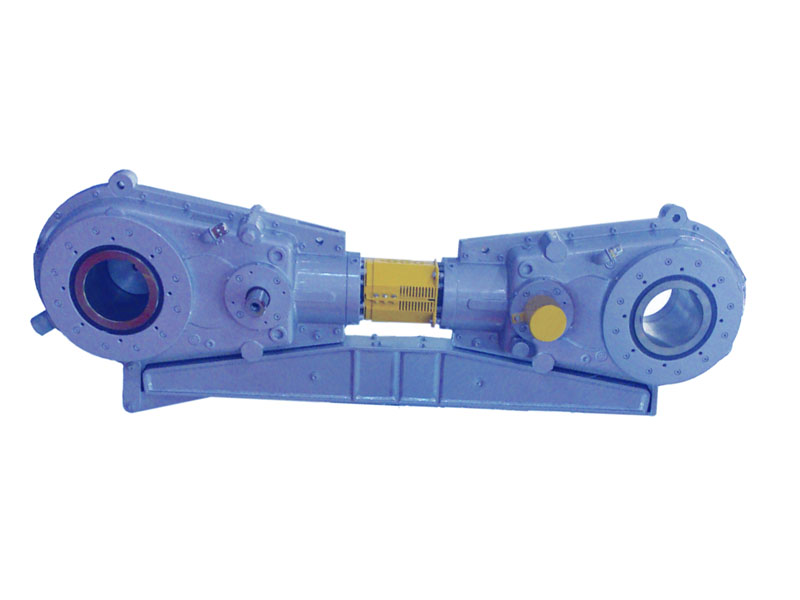

Three stage, hollow low speed shaft, bevel-helical gear unit

The single and tandem drives are ideal for board and paper machine rebuilds, thanks to their easy and quick installation and low maintenance requirement.

The single concept drives a single dryer cylinder with a single electric motor equipped with one drive reducer with a torque arm. Our tandem design drives a pair of dryer cylinders with a single electric motor equipped with a tandem drive reducer. The drive comprises two shaft-mounted gear reducers, which are interconnected through an intermediate steel disc coupling and a torque reaction bar. Since the connection allows for only limited movement between the gear units, some misalignment or runout of the cylinder journals is tolerated.

|

Technical data |

|

|

Design Sizes |

2 |

|

Number of Stages |

3 |

|

Power Range |

Max operating power 300 kW |

|

Transmission Ratio |

7 – 25 |

Compact, versatile and modular

The tandem drive unit can be installed in horizontal, vertical or diagonal positions. The unit is compact yet versatile and fits most dryer group layouts and sizes. The concept is also modular, so large groups can be driven using several units per group. The drive reducers are connected to a central lubrication system. The required oil flow is 8 litres/minute for each gear unit, i.e. 16 l/min for a tandem drive. Compact pressure lubrication units consisting of an oil tank, pumps, cooler and instrumentation are available as an option. The dryer cylinder steam coupling can be supported either by a gear unit housing or a separate support frame. The primary coupling between the electric motor and the tandem drive unit can be a universal shaft, an extended gear coupling or a steel disc coupling. The primary coupling and safety guard can be supplied to meet each case and its special requirements.