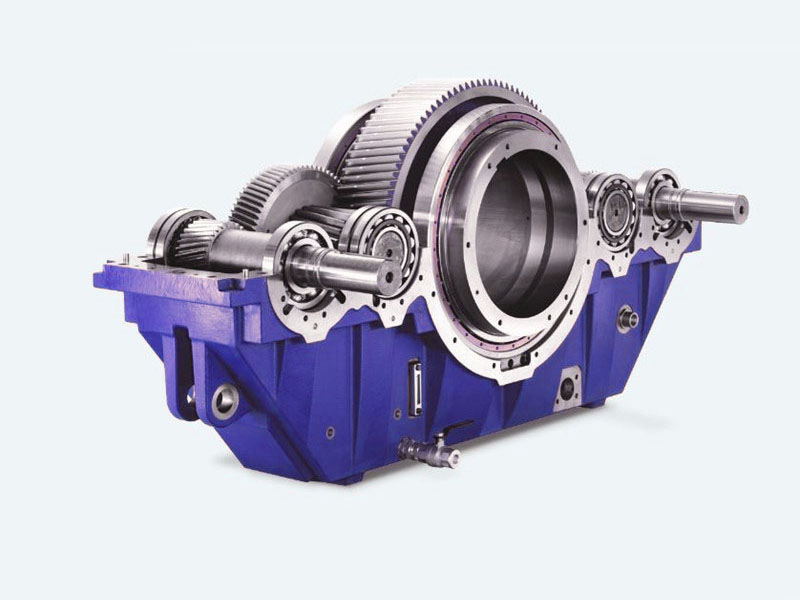

Yankee Cylinder Drives

Yankee cylinder drive units feature new, innovative technology to meet the requirements of today’s high-speed tissue machines. The Yankee cylinder drive features a unique pre-load arrangement of the main bearing, optimising load distribution, stabilising the operation of the Yankee gear unit and consequently extending bearing life. In addition, the Yankee Drive’s horizontal split lane housing delivers easy maintenance and low lifecycle costs.

Developed specifically for tissue machine applications, the Yankee cylinder drive units are engineered to be cost effective and maintenance friendly to lower our customers’ total cost of ownership.

Features & Benefits

- Single and double input options available

- Transmission ratio (5-140:1)

- Cost-effective and maintenance friendly structure

- Low lifecycle costs due to easy maintenance

- Optimal solution for production optimised tissue machines

- Advanced design housing

- Ability to handle up to 42 kN axial forces

- Can be equipped with a Sunday drive system

-

|

Size

|

|

2D2PHT100 2D2PHT110 2TMG450 2TMG500 2TMG560

|

|

I=5, 5.6, 6.3, 7.1, 8, 9, 10, 11.2, 12.5, 14, 16, 18, 20, 22.5, 25

|

|

3TMG450 3TMG500 3TMG560

|

|

I=25 28 31.5 35.5 40 45 50 56 63 71 80 90 100 112 125 140

|

Lubrication, cooling and locking

Heat generated by the steam used in a typical Yankee cylinder raises the operating temperature of the gear unit and puts additional demands on cooling and lubrication requirements. IINTEC gear units can be connected to a centralized lubrication and cooling system, or supplied with a separate lubrication system as per our customers’ requirements.

Key features of our overall system

Internal oil piping in the gear unit, which lubricates as well as removes heat from bearings and gears

Benefits of a INTECH lubrication system:

• A water cooled oil cooler provides heat exchange on the lubrication unit

• Dual pumps, lubrication systems and motors with one available to act as a back up in cases of low oil pressure or failure of a pump or motor

• Dual filter design enables one filter to be replaced without affecting the operation of the full system

Maximum low speed shaft bore diameters

Previous: Factory Free sample China NBR/PU/Silicone Material O-Ring Kit for Caterpillar Excavator

Next: Single & Tandem drives