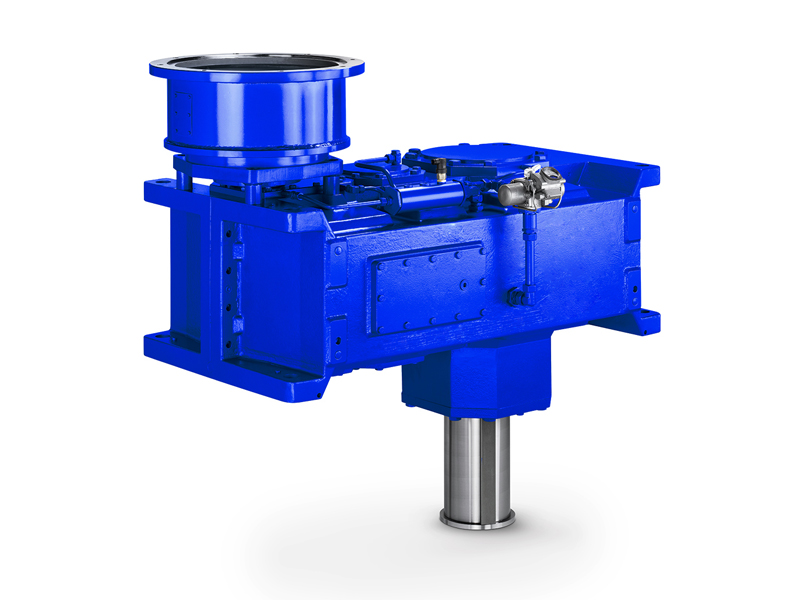

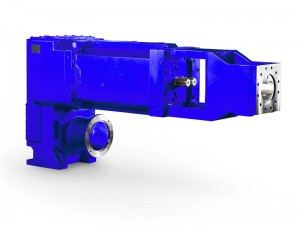

Gear units for aerator

Sizes:

H2BV05 H2BV06 H2BV07 H2BV08 H2BV09 H2BV10 H2BV11 H2BV12 H2BV13 H2BV14 H2BV15 H2BV16

H3BV05 H3BV06 H3BV07 H3BV08 H3BV09 H3BV10 H3BV11 H3BV12 H3BV13 H3BV14 H3BV15 H3BV16

B3BV05 B3BV06 B3BV07 B3BV08 B3BV09 B3BV10 B3BV11 B3BV12 B3BV13 B3BV14 B3BV15 B3BV16

• Oil pressure lubrication with flanged-on pump

• Reinforced bearings

• Dry well design (shaft seal is absolutely oil-tight)

• Coupling flange for mounting the aerator

• High operational reliability

• Low noise level

• High efficiencies

Strongly operating against biodegradable constituents

An aerator is an impeller in the biological part of a sewage treatment plant. It swirls the surface of the water so that it is enriched with oxygen. This activates the bacteria, so that the biodegradable constituents are removed from the sludge.

The impeller is fixed to the gear unit output shaft, which is extended vertically downward, a certain distance from the gear unit. To prevent the clarified water from becoming contaminated with gear oil, Gear units are designed with an output shaft featuring an oil retaining tube and a non-contacting, non-wearing shaft seal.

The axial and lateral loads resulting from the process are absorbed by extra-heavy-duty output shafts and output bearings.

Applications

• Wastewater treatment

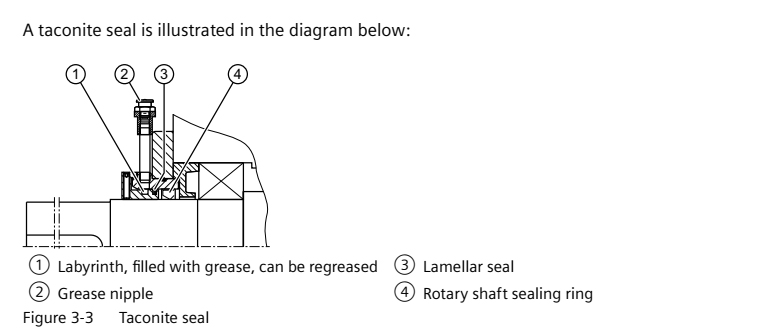

Taconite seal

The taconite seal is a combination of two sealing elements:

• Rotary shaft sealing ring to prevent the escape of lubricating oil

• Grease-filled dust seal (comprising a labyrinth and a lamellar seal) to allow operation of the

gear unit in extremely dusty environments

The taconite seal is ideal for use in dusty environments

Oil level monitoring system

Depending on the order specification, the gear unit can be equipped with an oil level monitoring system based on a level monitor, a level switch or a filling-level limit switch. The oil level monitoring system has been designed to check the oil level when the gear unit is at a standstill before it starts.

Axial load monitoring

Depending on the order specification, the gear unit can be equipped with an axial load monitoring system. The axial load from the worm shaft is monitored by a built-in load cell. Connect this to an evaluation unit provided by the customer.

Bearing monitoring (vibration monitoring)

Depending on the order specification, the gear unit can be equipped with vibration sensors,

sensors or with threads for connecting equipment for monitoring the rolling-contact bearings or gearing. You will find information about the bearing monitoring system design in the separate data sheet in the complete documentation for the gear unit.