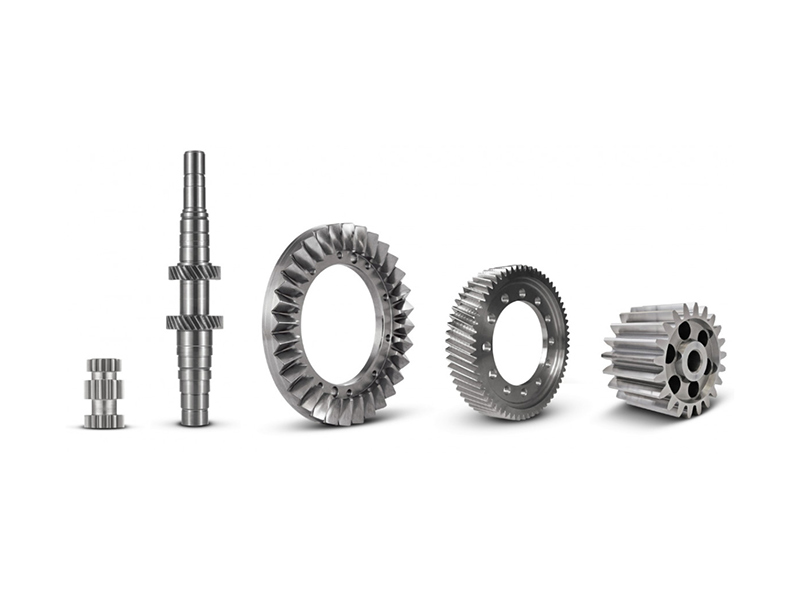

Spiral bevel gear parts

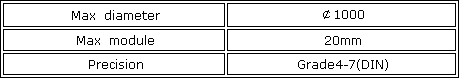

Product Parameters

Product Description

Gleason tooth and Klingelnberg tooth are available.

Gleason tooth spiral bevel gears are ground by Gleason CNC spiral bevel gear grinding machine.

Klingelnberg tooth spiral bevel gears are hob by Klingelnberg CNC spiral bevel gear cutting machine.

Gear process:

Forging, normalizing, chemical test, mechanical performance test, rough machining, Ultrasonic test, gear hobbing, heat treatment, carbon thickness test, hardness test, finish turning, grinding, gear grounding, magnetic powder test for crack, cleaning, package.

Application Engineering

We can help you design and evaluate all types of bevel and cylindrical gears, and greatly enhance their manufacturability and functionality, using powerful Gleason software such as GEMS (CAGETM, Unical, Finite Element Analysis and G-AGETM) and KISSsoft & KISSsys.