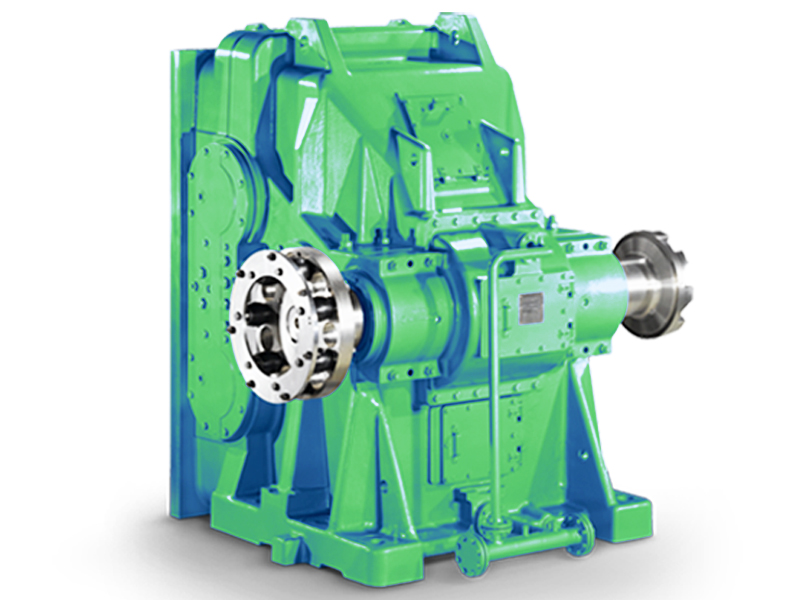

girth gear units for tubular mills

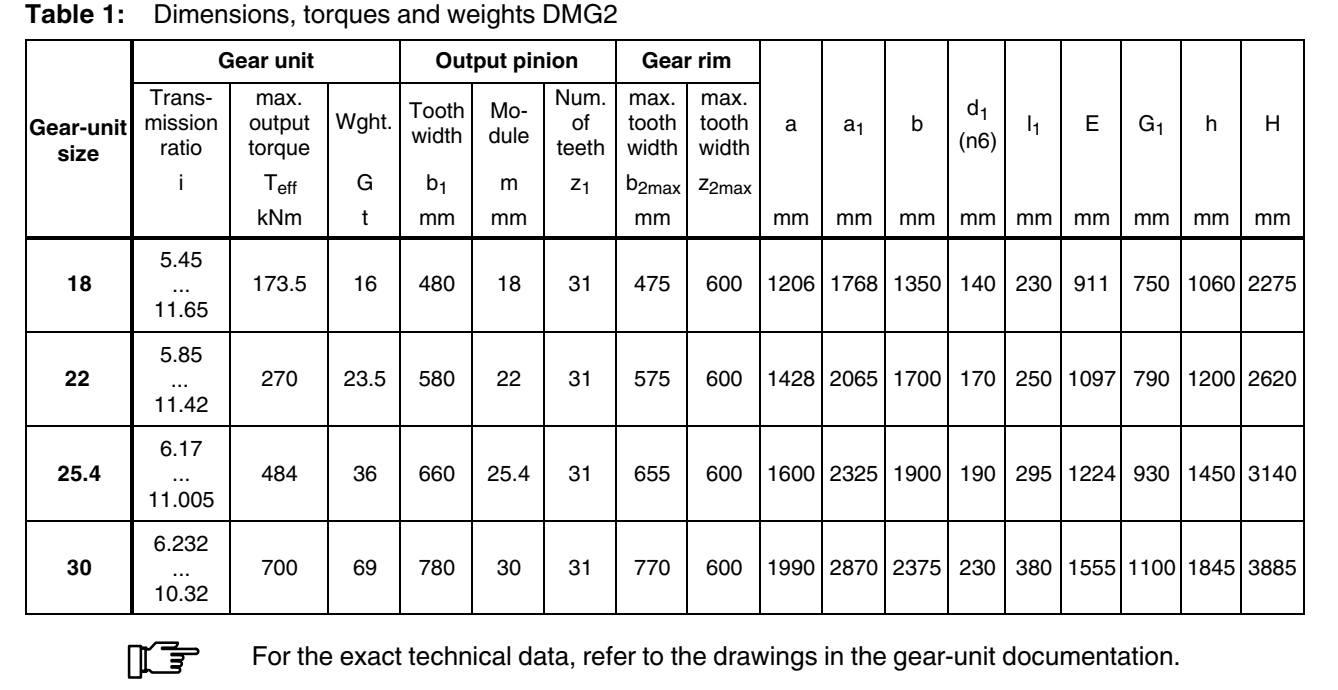

Sizes: DMG2-18 DMG2-22 DMG2-25.4 DMG2-30

DMGH18 DMGH22 DMGH-25.4 DMGH2-30

• Compact and efficient drive

• More effective use of the girth gear

• Perfect load distribution across the entire girth gear width

General description

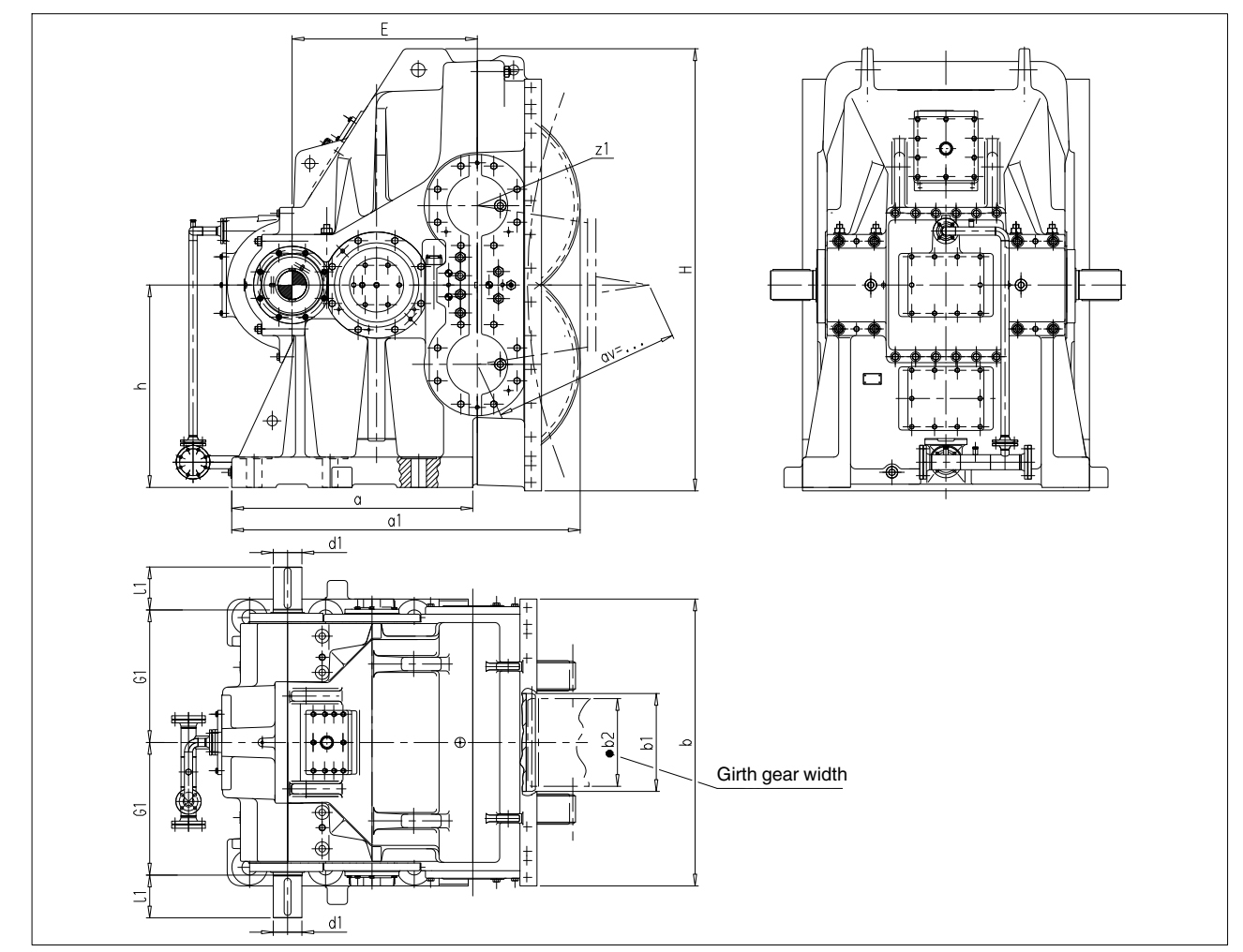

The "Girth gear unit" is a load¬ sharing helical gear unit for driving a tubular mill via a girth gear.

Its housing is not closed. Mounted on the shaft of the last stage is an output pinion. Both output pinions engage direct in the girth gear and are constructed to be able to compensate for unavoidable tilting and wrenching movements of the girth gear. This enables a good contact pattern over the whole teeth during operation.

The drive shaft of "Girth gear unit" is drawn out on both sides

DMG2 gear units is available in four sizes. Consistent standardization results in a high availability of individual components. The DMG2 gear units cover the entire power range from 1,200 to 10,000 kW in stand-alone operation and up to 20,000 kW with the use of a dual drive.

Compared to the traditional pinion/girth gear variant with external pinion and girth gear, the system with the gear unit for the girth gear is by far more favorable. Tried and tested elements were brought together in an optimal combination. Fewer parts are required, and consequently the space requirements, and the installation and operating costs are reduced. The current generation of

Applications

• Crushing of minerals, ores, coal, or cement clinker in the building materials industry and coal preparation

Lubrication

Both the teeth and the rolling bearings are force ¬lubricated by an oil supply unit. The lubricant is fed and distributed to the individual lubricating points by a suitably designed pipe system located on the inside of the gear unit. The nozzles and orifice plates used on it have large free cross¬ sections which have no tendency to blocking.

For an accurate view of the gear unit and oil ¬supply system, if any, please refer to the drawings in the gear unit documentation.

Shaft seals

Labyrinth seals at the both shaft outlets at the input side prevent oil from escaping from the housing and dirt from entering the gear unit. Labyrinth seals are non¬-contacting and so prevent wear to the shaft and ensure favorable temperature characteristics.

As the housing is designed to be open at the output and the output pinion engages in the girth gear direct there, no shaft seals are required here. However, the gear unit housing must be tightly attached to the girth gear cover.

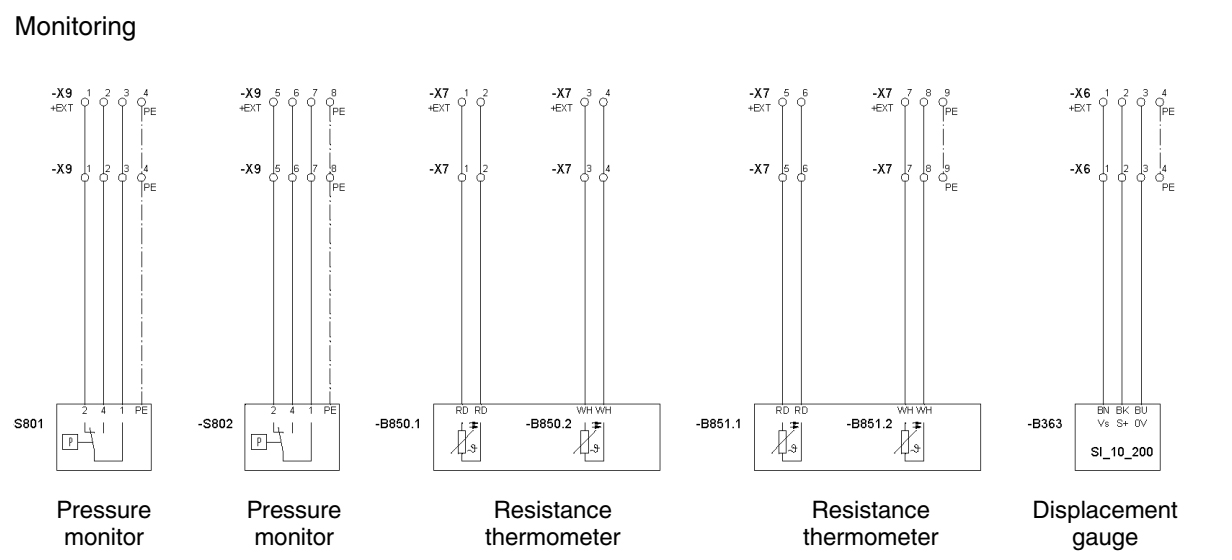

Terminal diagram

If necessary, 2 pressure monitors, 2 resistance thermometers and/or 1 displacement gauge can be mounted on the gear unit and wired in a terminal box. In this case the following description applies. If only one of the devices mentioned above is fitted and wired in the terminal box, only part of the description applies. In the case of additional installed devices the supplied documents of the operating instructions will apply.