To meet the customers' over-expected pleasure , now we have our potent staff to offer our greatest general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for Hydraulic Travelling Gear Reduction, Helical Gear Unit, Robot Reduction Gearbox, To acquire a consistent, profitable, and constant growth by getting a competitive advantage, and by continuously increasing the value added to our shareholders and our employee.

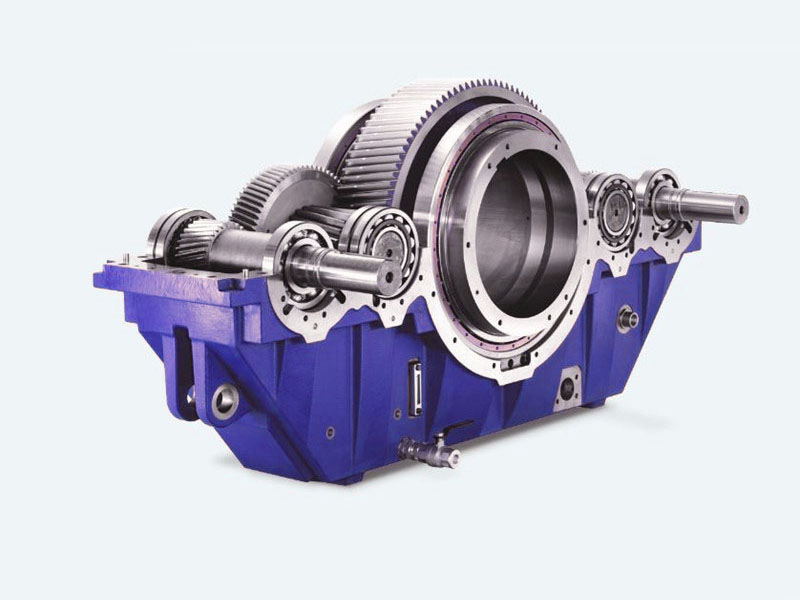

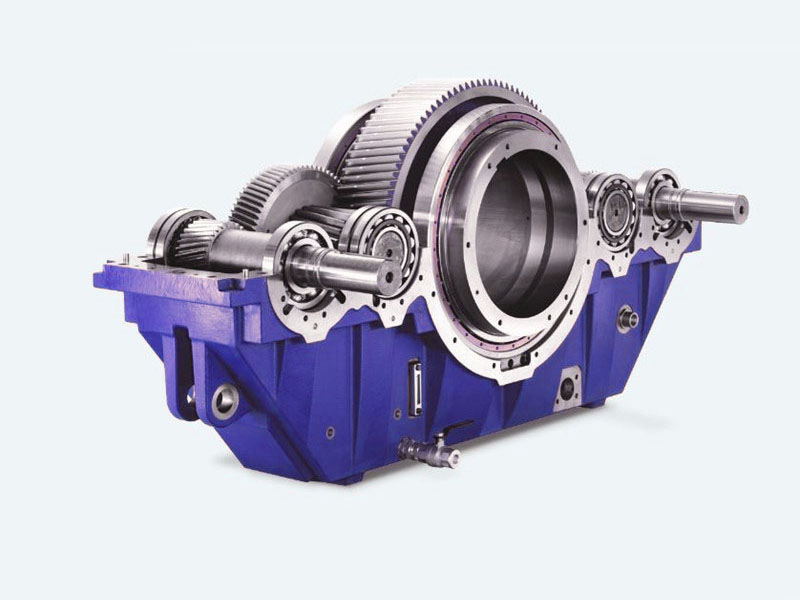

China Best Famous Rolling Mill Gear Reducer Factories - Yankee Cylinder Drives unit gearboxes – Intech Detail:

Yankee Cylinder Drives

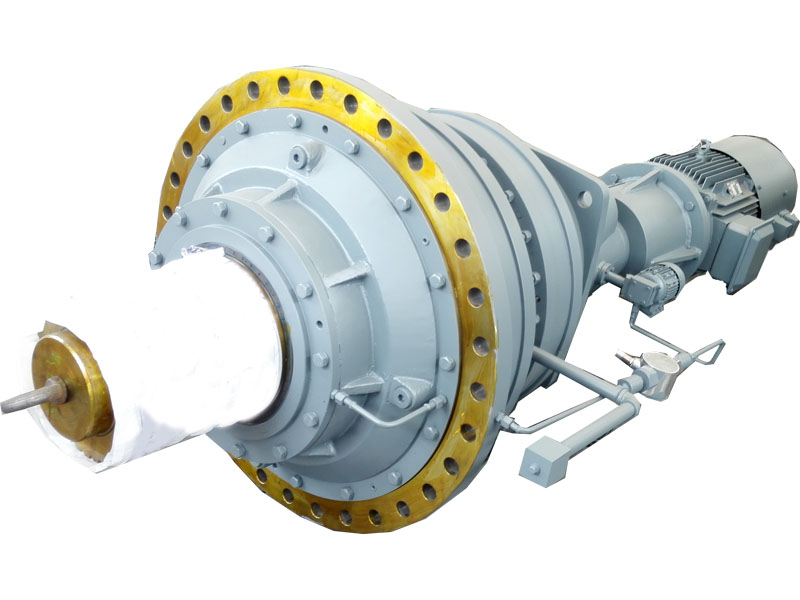

Yankee cylinder drive units feature new, innovative technology to meet the requirements of today’s high-speed tissue machines. The Yankee cylinder drive features a unique pre-load arrangement of the main bearing, optimising load distribution, stabilising the operation of the Yankee gear unit and consequently extending bearing life. In addition, the Yankee Drive’s horizontal split lane housing delivers easy maintenance and low lifecycle costs.

Developed specifically for tissue machine applications, the Yankee cylinder drive units are engineered to be cost effective and maintenance friendly to lower our customers’ total cost of ownership.

Features & Benefits

- Single and double input options available

- Transmission ratio (5-140:1)

- Cost-effective and maintenance friendly structure

- Low lifecycle costs due to easy maintenance

- Optimal solution for production optimised tissue machines

- Advanced design housing

- Ability to handle up to 42 kN axial forces

- Can be equipped with a Sunday drive system

-

|

Size

|

|

2D2PHT100 2D2PHT110 2TMG450 2TMG500 2TMG560

|

|

I=5, 5.6, 6.3, 7.1, 8, 9, 10, 11.2, 12.5, 14, 16, 18, 20, 22.5, 25

|

|

3TMG450 3TMG500 3TMG560

|

|

I=25 28 31.5 35.5 40 45 50 56 63 71 80 90 100 112 125 140

|

Lubrication, cooling and locking

Heat generated by the steam used in a typical Yankee cylinder raises the operating temperature of the gear unit and puts additional demands on cooling and lubrication requirements. IINTEC gear units can be connected to a centralized lubrication and cooling system, or supplied with a separate lubrication system as per our customers’ requirements.

Key features of our overall system

Internal oil piping in the gear unit, which lubricates as well as removes heat from bearings and gears

Benefits of a INTECH lubrication system:

• A water cooled oil cooler provides heat exchange on the lubrication unit

• Dual pumps, lubrication systems and motors with one available to act as a back up in cases of low oil pressure or failure of a pump or motor

• Dual filter design enables one filter to be replaced without affecting the operation of the full system

Maximum low speed shaft bore diameters

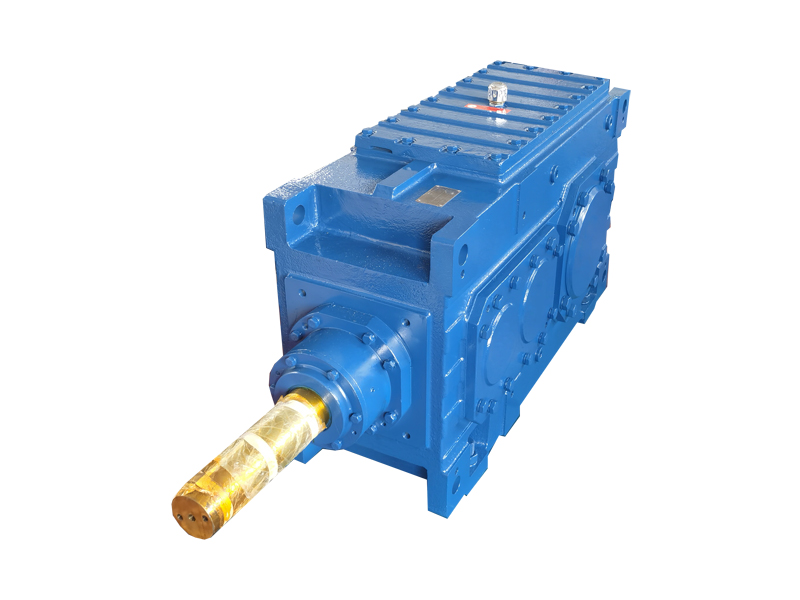

Product detail pictures:

Related Product Guide:

Cooperation

Our workforce through professional training. Skilled professional knowledge, solid sense of service, to fulfill the services demands of consumers for China Best Famous Rolling Mill Gear Reducer Factories - Yankee Cylinder Drives unit gearboxes – Intech, The product will supply to all over the world, such as: Poland, Irish, Lyon, Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We will continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!