For the lubrication of open gear drives used in different industrial applications such as cement and coal mills, rotary furnaces, or where the sealing conditions are difficult, semi-fluid greases are often used in preference to fluid oils. For girth gear applications the greases are used with a splash or spray lubrication system. The selection of such greases influences pitting life- time and the load-carrying capacity of the gears, as well as wear behavior.

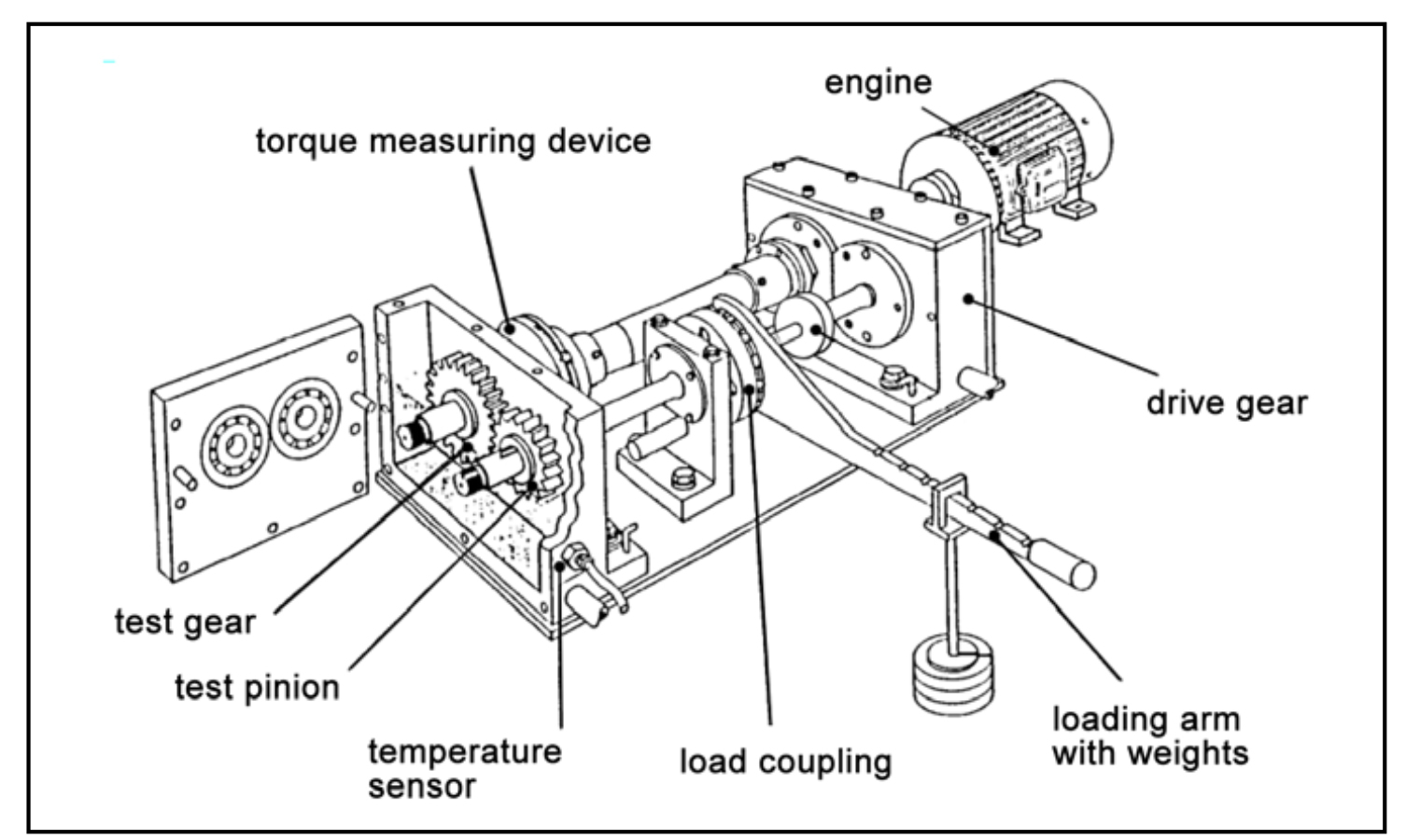

Investigations have been carried out making comparisons between a fluid oil and different semi-fluid (NLGI00) grease formulations, varying with regard to base oil viscosity, thickener type and the addition of both liquid and solid additives. The test runs for the determination of the different parameters were performed on back-to-back gear test rigs; the schematic setup of the test rig is shown bellow.

The test results show that gear greases of NLGI 00 consistency exhibit almost the same pitting lifetime as their base oil counterparts. Furthermore, the kinematic viscosity of the base oil shows a significant influence on pitting lifetime of such NLGI 00 grade greases. The addition of a special synthetic graphite to such a gear grease led to a decrease in pitting life and high wear. The test results also show that the pitting load carrying capacity of these greases correlates with the kinematic viscosity of the base oil. Using a higher base oil viscosity, longer pitting lifetime and higher pitting load carrying capacity were achieved. For semi-fluid gear greases, the calculation of pitting load carrying capacity according to ISO 6336 using the viscosity of the base oil correlates well with the practical test results. The tests to analyze wear behavior of different semi-fluid gear greases were made in the wear test A/2.8/50 on the basis of ISO 14635-3 and ISO 14635-1. Four different wear categories were defined for the 100-hour endurance test and a classification made according to the wear sum on the pinion and wheel. Generally speaking, almost all investigated lubricants, with the exception of greases containing solid lubricants, show low wear in all test parts. The in fluence of the base oil viscosity can be seen in that greases with higher base oil viscosities exhibit lower wear. The influence of the concentration of thickener and the type of thickener is almost negligible, but the grease with an aluminum complex soap does show just a very slight higher wear sum compared to its lithium soap-thickened counter- part. A much more significant difference can be seen in the influence of the amount and type of solid lubricant. Greases containing synthetic graphite exhibit much higher wear sums — correlating with the amount of graphite in the grease — compared to the same grease with no solid lubricants. At the end of the step test the grease containing 4.2% graphite shows a three-times- higher wear sum than the base grease. And with a higher amount of graphite — 11.1% —the wear sum increased to a level of eight times higher com- pared to the grease with no solids. This trend was also confirmed in the endurance test; i.e. — the more graphite, the higher the wear. On the other hand, the grease containing 4.2% of molybdenum disulphide displays comparable wear. When the spur gearset starts to rotate, the grease next to the gearset is immediately discarded and does not return to that gearset due to the lack of a sufficient replenishment mechanism. A gap is formed between the rotating gears and the grease sump. No fresh grease flows from the sump to the gearset because of its solid consistency. A lack of lubrication and cooling can be observed that can lead to high bulk temperatures in the gears and, finally, to scuffing. Only a small amount of grease participates in the lubrication. Channeling occurs mainly at 40 and 50% filling levels and for stiffer prod to the base grease after the step test and only slightly higher wear after the endurance test.

In a different context, for the lubrication of small, enclosed gear drives used in electrical tools or in medical applications, as well as for the lubrication of small gearboxes in difficult sealing conditions, stiffer greases are preferred, often of NLGI 1 or 2 grade consistency. The selection of grease type and the filling level influence efficiency, load-carrying capacity and heat transfer in a gearbox.

Post time: Aug-10-2021